Structural integrity is a critical factor in ensuring the safety and longevity of various engineering structures, from pipelines and tanks to bridges and buildings. One of the key parameters that directly impacts structural integrity is the thickness of the walls that make up these structures. Monitoring and maintaining the appropriate wall thickness is essential to prevent corrosion, wear, and other forms of deterioration that can compromise their stability and safety.

In the past, measuring wall thickness was a labor-intensive and often inaccurate process. Engineers and inspectors had to rely on traditional methods such as ultrasonic testing and visual inspections, which had their limitations. However, with advancements in technology, modern wall thickness measuring equipment tools have revolutionized the way we assess and enhance structural integrity.

In this article, we will explore how modern wall thickness measurement tools have transformed the field of structural engineering and why they are essential for maintaining the safety and reliability of critical infrastructure.

The Importance of Wall Thickness in Structural Integrity

Before delving into the benefits of modern measurement tools, it’s crucial to understand why wall thickness is such a critical parameter in structural integrity.

Corrosion Protection: In many applications, structures are exposed to harsh environmental conditions, including moisture, chemicals, and temperature fluctuations. Over time, this exposure can lead to corrosion and thinning of the walls. Monitoring wall thickness allows engineers to identify areas at risk and take preventive measures.

Safety Assurance: Ensuring that the walls of a structure meet specified thickness requirements is vital for the safety of people and the environment. Thin or weakened walls can lead to catastrophic failures, posing significant risks to human life and the ecosystem.

Longevity and Durability: Maintaining the proper wall thickness can significantly extend the lifespan of a structure. By identifying and addressing thinning areas early, it is possible to prevent costly repairs or replacements.

The Evolution of Wall Thickness Measurement Tools

In the past, assessing wall thickness relied on invasive methods that often required shutting down operations, cutting into structures, or even complete disassembly. These methods were not only time-consuming but also posed risks to the integrity of the structure itself. Modern wall thickness measurement tools have revolutionized this process in several ways:

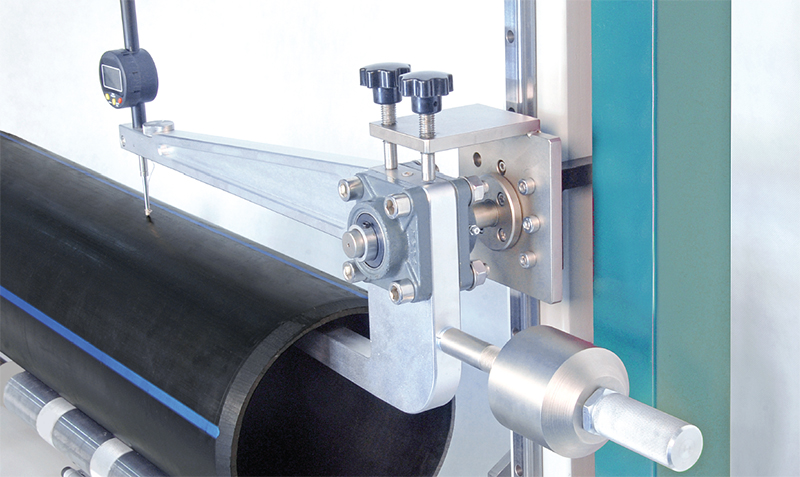

Non-Destructive Testing (NDT): Advanced NDT techniques, such as ultrasonic thickness gauges, use sound waves to measure wall thickness without damaging the structure. This technology provides accurate results and eliminates the need for invasive inspections.

Remote Monitoring: Many modern tools are equipped with remote monitoring capabilities. This means that engineers can continuously monitor wall thickness in real-time, allowing for proactive maintenance and reducing the risk of unexpected failures.

Digitalization: Wall thickness data can now be digitized and stored in databases, making it easier to track changes over time and plan maintenance activities more effectively. This digital approach also allows for predictive analytics to forecast potential issues.

Precision and Accuracy: Modern measurement tools offer high levels of precision and accuracy, ensuring that engineers can make informed decisions about the structural integrity of a component or system.

Applications of Modern Wall Thickness Measurement Tools

Modern Wall Thickness Measuring Equipment tools find applications in a wide range of industries and sectors:

Oil and Gas: In the oil and gas industry, pipelines are subjected to corrosive substances. Wall thickness measurement tools help prevent leaks and ruptures that could have disastrous environmental and economic consequences.

Aerospace: Aircraft components must meet stringent safety standards. Wall thickness measurements are crucial for identifying potential weaknesses and ensuring the durability of aircraft structures.

Manufacturing: In manufacturing, ensuring the thickness of pressure vessels, tanks, and other containers is essential for safety and quality control.

Infrastructure: Bridges, tunnels, and buildings benefit from regular wall thickness assessments to ensure their longevity and safety for the public.

Maritime: Ships and offshore structures are exposed to harsh marine environments. Regular monitoring of wall thickness is essential to prevent corrosion and maintain seaworthiness.

Conclusion

Modern wall thickness measurement tools have transformed the way engineers and inspectors assess structural integrity. These advanced tools offer non-destructive testing, remote monitoring, digitalization, and high precision, making it easier to maintain the safety and longevity of critical infrastructure across various industries. As technology continues to advance, we can expect even more sophisticated measurement tools to further enhance our ability to safeguard structural integrity in the future.